Ball Screws

Why Thomson Ball Screws?

Not all precision ball screws are created equal. At Thomson, our careful attention to design, quality, materials, manufacturing and application support has set us apart from the competition and created an ideal recipe for success that has lasted for decades.

Customization Options

When standard Thomson ball screws don’t meet your exact specification requirements, our engineering experts can help customize a solution for your application. Whether it’s one or a large quantity, a simple component modification or complex assembly, our custom capabilities can meet your needs and improve your machine’s performance.

Ball Screws

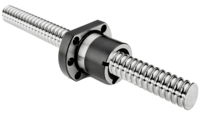

A ball screw is a mechanical device for translating rotational motion to linear motion with little friction.

A threaded shaft provides a spiral raceway for ball bearings which act as a precision screw.

As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction.

They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary.

The ball assembly acts as the nut while the threaded shaft is the screw.

- D = 12 – 200 mm

- pitch: 4 – 80 mm

- Lmax: 7000 mm

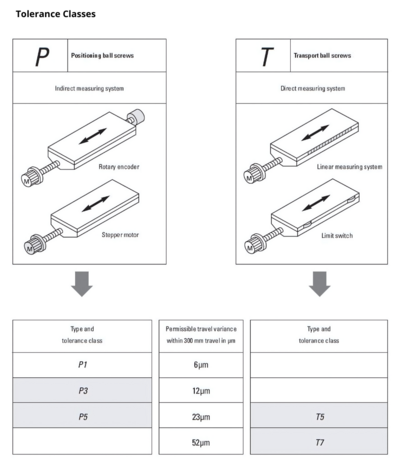

- accuracy class: P1 - T7

Miniature TSI & PRM Rolled Ball Screws

Assemblies are an efficient and cost-effective solution in a small envelope, ideal for use in small spaces.

Ball screw assemblies range from 4 to 14mm in diameter with leads from 1 to 20mm - all with standard lead accuracies of ±52µm/300mm.

Miniature Rolled Ball Screws are ideal for laboratory, semiconductor, and medical applications.

Tech tips

Motorized Lead Screw with Taper-Lock

How to Transfer a Ball Nut to a Ball Screw

Identifying Your Ball Screw Assembly